Lassen Sie den neuesten Stand der Technik für sich arbeiten!

Die Forstner nuSLIT – Serie bringt die Produktion Ihrer Zuschnitte, sowohl in Hinsicht auf die Flexibilität als auch auf die Produktivität, auf ein ganz neues Level.

CIDAN Machinery stellt Längs- und Querteilanlagen her, die von erfahrenen und ungelernten Anwendern programmiert und bedient werden können. Unsere Ablängmaschinen sind All-in-One-Einheiten, die so konstruiert sind, dass sie einer hohen Produktion im Laufe der Zeit standhalten und gleichzeitig so wenig Platz wie möglich beanspruchen.

CIDAN Machinery bietet viele seiner hochmodernen Funktionen serienmäßig an – Richteinheit, Blechführung für den Vorschub, Tafelscheren mit Niederhalter und zweischneidige Messer, Vorschubeinheiten, Fußpedale für die Fernbedienung und vieles mehr.

Um die absolut besten technologischen Möglichkeiten zur Coilbearbeitung rund um den Globus anbieten zu können, ist inzwischen auch Forstner, die seit 1960 weltweit führende Marke für Längs- und Querteilanlagen, Teil der

CIDAN Machinery Gruppe.

Lassen Sie den neuesten Stand der Technik für sich arbeiten!

Die Forstner nuSLIT – Serie bringt die Produktion Ihrer Zuschnitte, sowohl in Hinsicht auf die Flexibilität als auch auf die Produktivität, auf ein ganz neues Level.

Typ: Längs- und Querteilanlage Blechbreite: 1.250 mm Kapazität: 1,0 mm

Stark und zuverlässig

Die Forstner POWER COMPACT PRO vereint maximale Schnittleistung und minimalen Platzbedarf.

Typ: Längs- und Querteilanlage Blechbreite: 1.250/1.500 mm Kapazität: 2,0/1,70 mm

Leistungsstark und dennoch kompakt

Die Forstner COMPACT ist die perfekte Kombination und kann in kleineren Werkstätten, sowie in größeren Unternehmen mit serienmäßiger Produktion eingesetzt werden.

Typ: Längs- und Querteilanlage Blechbreite: 1.250/1.500 mm Kapazität: 1,0 mm

Maßgenaue und flexible Zuschnitte vom Breitband

Die Forstner SLIT Längs- und Querteilanlage ist aus langjähriger Erfahrung optimal für alle Spenglerbetriebe geeignet.

Typ: Längs- und Querteilanlage Blechbreite: 1.250/1.500 mm Kapazität: 1,0 mm

Richten und Schneiden auf geringstem Platz mit dem effektivsten Ergebnis

Die Forstner POWER STRAIGHT PRO ist die schwere Ausführung zur STRAIGHT PRO, noch massivere Richtwellen garantieren auch bei stärkeren Blechen ein perfektes Richtergebnis

Typ: Querteilanlage Blechbreite: 1.250/1.500 mm Kapazität: 2,0 mm

Schnell, stark und zuverlässig

Die Forstner STRAIGHT zeichnet sich durch hocheffiziente Schnitte von Coils aus.

Typ: Querteilanlage Blechbreite: 1.250/1.500 mm Kapazität: 1,0 mm

Perfekte Ergebnisse im Handumdrehen

Die Forstner EASY mit Richtwalzen ist die ultimative Querteilanlage für die Blechbearbeitung in der Bauindustrie.

Typ: Querteilanlage Blechbreite: 1.250 mm Kapazität: 1,0/1,5 mm

Leistungsstarkes, motorgetriebenes Abwickelgerät für eine höhere Produktionsgeschwindigkeit

Das motorisierte Abwickelgerät Modell D von Forstner ist eine für die Hochgeschwindigkeitsproduktion entwickelte leistungsstarke und elegante motorgetriebene Abwickelhaspel für Coils mit einem Gewicht von 5 oder 8 Tonnen.

Typ: Abwickelgerät Coilbreite: 1.500 mm Kapazität: 5 oder 8 Tonnen

Manuelles Abwickelgerät mit hoher Kapazität

Abwickelgerät für große Coils. Ein starker Helfer mit einer Kapazität von bis zu 5 Tonnen und einem Außendurchmesser von bis zu 1.100 mm. Das manuelle Abwickelgerät von Forstner ist mit einem spreizbaren Mitteldorn und einer einstellbaren Bremse ausgestattet.

Typ: Abwickelgerät Coilbreite: 1.250/1.500 mm Kapazität: 5.000 kg

Manuelles Abwickelgerät mit spreizbarem Dorn, einseitig gelagert

Manuelles Abwickelgerät mit spreizbarem Dorn. Einseitig gelagert für einen schnellen Coilwechsel.

Typ: Abwickelgerät Coilbreite: 1.250 mm Kapazität: 2.000 kg

Doppelte Kapazität auf der selben Fläche!

Der manuelle Abwickelturm ist eine Lösung, für die sich viele Kunden begeistern. Auf der selben…

Typ: Abwickelgerät Coilbreite: Max. 1.250 mm Kapazität: 2 x 2.000 kg

Meister im Sparen von Platz und Zeit.

Der CIDAN COILMASTER schafft Ordnung in Ihrer Werkstatt. Sie haben die volle Kontrolle über Ihre verschiedenen Coils und Materialqualitäten. Nutzen Sie die Höhe und sparen Sie Stellfläche. Gleichzeitig sparen Sie Zeit und Geld durch kurze Rüstzeiten und minimieren das Risiko einer Materialbeschädigung.

Typ: Coilmaster Länge: 2 bis 4 Meter Kapazität: 4 bis 8 Tonnen

mit 4 Stützrollen und 2 Seitenrollen

für kleinere Coils bis max. 1.000 kg und 1.250 mm Breite

Typ: Abwickelgerät Coilbreite: 1.250 mm Kapazität: 1.000 kg

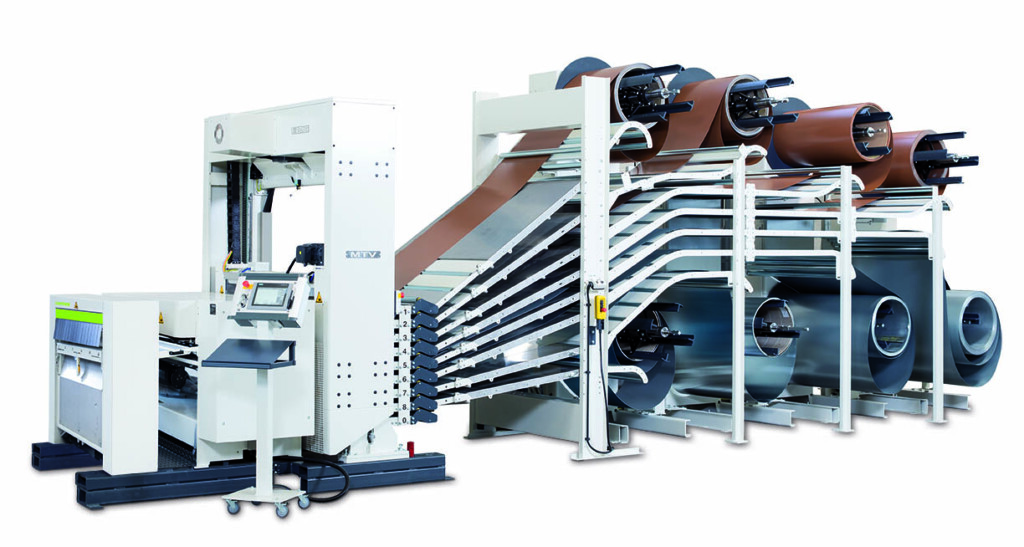

Wechselt das Blech in kürzester Zeit!

Motorisierter Mehrfachtisch, der sich in kürzester Zeit um den Blechwechsel kümmert. Drücken Sie einfach auf einen Knopf, und schon steht das gewünschte Material für die Längs- und Querteilung bereit!

Typ: Blechwechsel Coilbreite: max. 1500 mm Anzahl Coils: max. 6 Stk.

Vereinfacht die Handhabung verschiedener Coils

Der manuelle Spannbock ist eine sehr wirtschaftliche Lösung für den schnellen und einfachen Blechwechsel bei einer Längs- und/oder Querteilanlage.

Typ: Blechwechsel Coilbreite: max. 1500 mm Anzahl Coils: max. 8 St.